The Videojet printhead is a crucial component that enables fast and high-quality printing. Manufactured with special technologies by Videojet, these components allow seamless and uninterrupted printing and labeling operations in industrial production lines. You can choose a Videojet printhead model that best suits your needs and expectations.

What is a Videojet Printhead and What Does It Do?

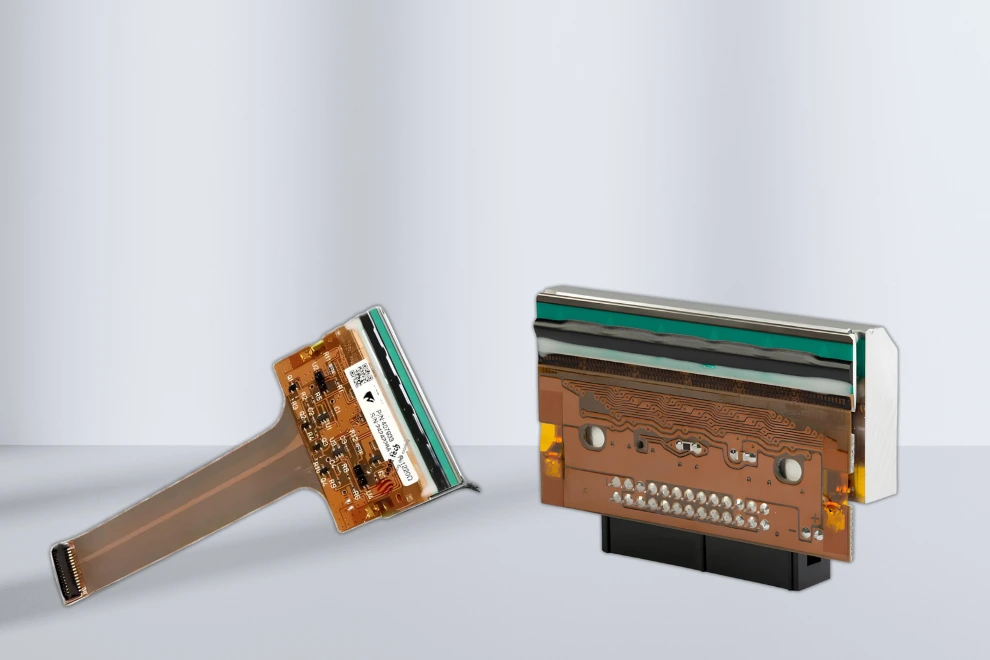

A Videojet printhead is one of the core mechanical parts of the printer that performs the printing process. Operating with thermal transfer technology, these heads transfer ink from the ribbon to the product surface with high precision, ensuring that information such as dates, serial numbers, and barcodes are printed clearly and permanently.

The printhead directly affects print quality. A clean and properly functioning head delivers superior print quality, while a damaged or dirty head can cause printing errors. Videojet printheads stand out with their long service life and low maintenance requirements.

Videojet Printhead Models and Features

Videojet printhead models can be used in intermittent or continuous printing modes depending on production line requirements. Additionally, the ribbon path is simplified, and ribbon replacement is fast, which enhances operational efficiency and printing speed.

With weekly cleaning using ink-compatible cleaning solutions, these printheads can be used reliably for many years. However, if printhead performance decreases or inkjet issues arise, replacement may be necessary. This process requires professional equipment and expertise.

Popular Videojet Printhead Models

Videojet printheads are available in different print widths and resolution options. Highlighted models and their technical specifications are as follows:

| Model | Print Width (mm) | Resolution (dpi) | Maximum Print Speed |

| Videojet 6230 | 32 mm | 300 dpi | 150 packs/min |

| Videojet 6530 | 53 mm | 300 dpi | 250 packs/min |

| Videojet 6330 | 53 mm | 300 dpi | 250 packs/min |

| Videojet 9550 LPA | 107 mm | 300 dpi | High-speed |

Why Choose a Videojet Printhead?

Videojet printhead models are widely preferred by brands due to the advantages they provide to production lines. The main reasons for choosing these printheads include:

- High Print Quality: Enables clear, legible, and permanent printing with resolutions of 300 DPI and above.

- Durability and Reliability: Extremely durable thanks to a long-lasting head structure and high-quality materials.

- Ease of Use: Fast ribbon changes and the user-friendly CLARiTY™ touch interface allow practical operation.

- Increased Efficiency: Airless operation and iAssure™ quality control technology ensure uninterrupted production.

- Flexible Application Areas: Different print widths and speed options make them adaptable to various production lines.

Which Industries Use Videojet Printheads?

Due to their practical use, Videojet printheads are widely used across different industries. In the food and beverage industry, they are ideal for printing batch numbers, expiration dates, and barcodes directly onto products. In the pharmaceutical and healthcare sectors, Videojet printheads provide high-quality coding for product traceability and regulatory compliance. Furthermore, in the automotive and electronics industries, they are frequently used for printing serial numbers and part identifications onto products and components.

With Videojet printhead models, which stand out in the printing technologies industry, you can achieve high-quality, fast, and reliable printing operations. To explore our products and services that enable efficient and secure labeling and printing processes, visit our website: https://dgs.com.tr/en/.