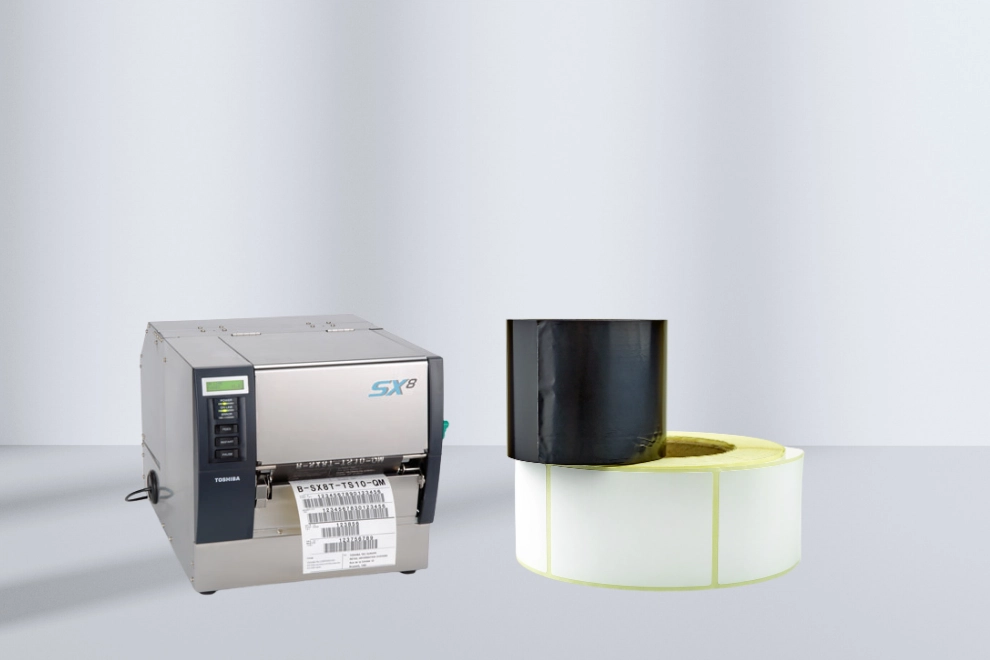

In thermal transfer printing technology, ribbon models vary depending on label lifespan, durability, and cost requirements. The differences between wax, wax/resin, resin, and colored ribbons arise from their ink compositions and application areas. This article guides businesses in increasing printing efficiency by selecting the right ribbon.

What Is a Wax Ribbon, What Is It Used For, and Its Application Areas

A wax ribbon is the most economical thermal transfer ribbon model, containing wax-based ink. It melts with heat and enables high-speed printing on paper labels (coated, vellum).

Main application areas:

- Shelf labels, price tags, and in-warehouse logistics labels

- Indoor, short- to medium-term paper-based printing

- Offers low cost and high printing speed but has limited resistance to moisture and abrasion

What Is a Wax/Resin Ribbon, What Is It Used For, and Its Application Areas

A wax/resin ribbon is a hybrid model that provides mid-level performance with a mixture of wax and resin. It can be used on both paper and synthetic labels (PE, PP).

Main application areas:

- Shipping labels, textile, food, and cold-chain applications

- Printing requiring moderate durability for indoor and limited outdoor use

- More resistant than wax and a more economical intermediate solution compared to resin

What Is a Resin Ribbon, What Is It Used For, and Its Application Areas

A resin ribbon is the most durable thermal transfer ribbon model, based on resin ink. It provides permanent printing on synthetic labels (PVC, PET) under extreme conditions.

Main application areas:

- Automotive, chemical, electronics, and laboratory labels

- Outdoor environments and exposure to chemicals and high temperatures

- Despite its higher cost, it reduces total cost of ownership thanks to its long lifespan

What Is a Colored Ribbon, What Is It Used For, and Its Application Areas

A colored ribbon is a special model that offers multicolor printing (red, blue, green, etc.) using wax or wax/resin-based pigmented inks.

Main application areas:

- Promotional labels and color-coded shelf markings

- Visual marketing and organizational labeling

- Provides color variety, but durability depends on the base model (wax or wax/resin)

Differences Between Ribbon Models

The differences between ribbon models are summarized in the table below:

| Feature | Wax Ribbon | Wax/Resin Ribbon | Resin Ribbon | Colored Ribbon |

| Ink Composition | Wax | Wax + Resin | Resin | Wax / Wax-resin + color |

| Durability | Low–Medium | Medium | High | Depends on base model |

| Label Type | Paper | Paper + Synthetic | Synthetic | Paper + Synthetic |

| Cost | Lowest | Medium | High | Medium–High |

| Usage Environment | Indoor | Indoor + limited outdoor | Outdoor + extreme | Indoor |

| Color Options | Black | Black | Black | Multicolor |

| Example Use | Shelf label | Shipping label | Chemical label | Promotional label |

Label lifespan, environmental conditions, and budget are the key factors in selection: wax ribbons are suitable for short-term indoor use, while resin ribbons are preferred for harsh conditions.

If you want to improve your print quality with the right ribbon selection, DGS Printing Technologies is by your side. A leader in labels, ribbons, and thermal transfer systems since 2000, DGS stocks all ribbon models through original imports. With products supplied from global brands such as ITW Thermal Films and Ricoh, DGS offers tailored solutions for your business. For detailed information and orders, you can visit dgs.com.tr/en/ and get in touch.