Thermal transfer ribbon prices are directly influenced by ink composition, manufacturing quality, and performance characteristics. Price differences among wax, wax/resin, resin, and colored ribbon models are shaped by the durability and application flexibility they offer. This article guides businesses in making the right ribbon selection while planning their budgets.

What Is a Wax Ribbon? Purpose, Features, and Applications

Wax ribbons are the most basic and cost-effective thermal transfer ribbon type, formulated with a wax-based ink. They melt under heat to provide fast printing on paper labels.

Features:

They offer low energy consumption, high printing speed, and good contrast; however, they have limited resistance to environmental factors.

Applications:

- Shelf labels, price tags, and in-warehouse logistics labels

- Indoor, short- to medium-term paper-based printing

Their price advantage stands out in high-volume standard printing applications.

What Is a Wax/Resin Ribbon? Purpose, Features, and Applications

Wax/resin ribbons provide balanced performance through a blend of wax and resin. They deliver effective results on both paper and synthetic labels.

Features:

More resistant than wax ribbons and more economical than resin ribbons; they provide medium-level protection against abrasion and moisture.

Applications:

- Shipping, textile, food, and cold chain labels

- Indoor and limited outdoor applications

Their price/performance balance makes them ideal for versatile labeling needs.

What Is a Resin Ribbon? Purpose, Features, and Applications

Resin ribbons are premium thermal transfer ribbons formulated with resin-based ink, offering maximum durability. They ensure permanent printing on synthetic surfaces.

Features:

Superior resistance to chemicals, mechanical abrasion, and environmental conditions; they deliver long-lasting results.

Applications:

- Automotive, chemical, electronics, and laboratory labels

- Outdoor use and extreme environments

Although the initial cost is higher, they provide long-term savings by reducing the need for reprinting.

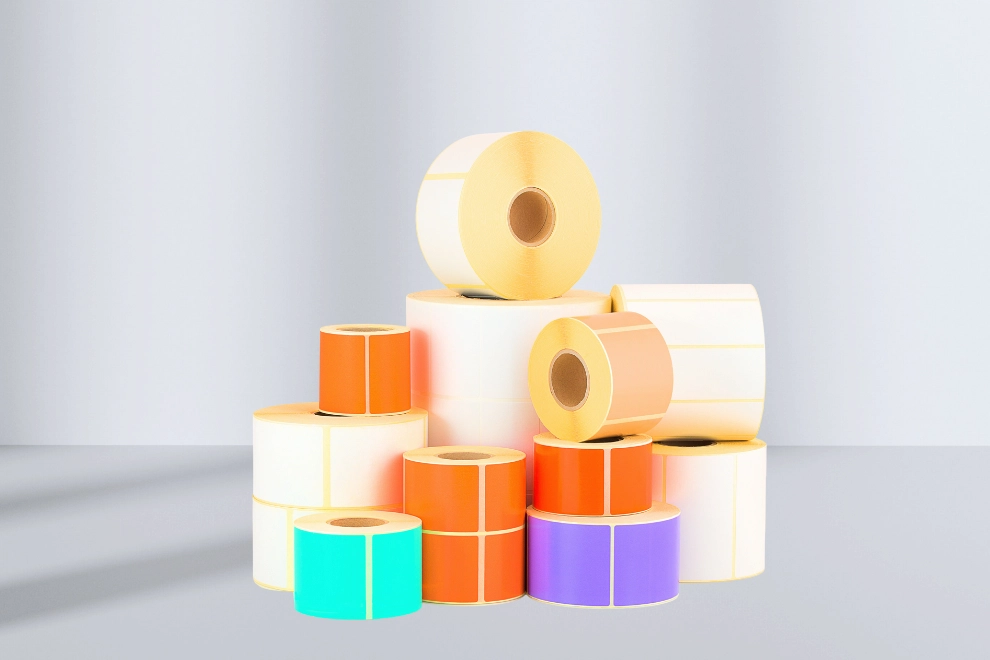

What Is a Colored Ribbon? Purpose, Features, and Applications

Colored ribbons are special ribbon types that use pigmented inks to produce multi-color printing (red, blue, etc.). They are generally wax/resin-based.

Features:

Vivid color tones and visual diversity, with durability depending on the base ribbon formulation.

Applications:

- Promotional labels and color-coded shelf markings

- Marketing materials and organizational labels

Due to their specialized formulation, they fall into a higher price segment.

Differences in Ribbon Prices

Ribbon price differences result from material quality and performance levels. The table below summarizes the main distinctions.

| Feature | Wax Ribbon | Wax/Resin Ribbon | Resin Ribbon | Colored Ribbon |

| Price Level | Lowest | Medium | Highest | Medium–High |

| Durability | Low–Medium | Medium | High | Depends on base type |

| Label Type | Paper | Paper + Synthetic | Synthetic | Paper + Synthetic |

| Print Speed | Very High | High | Medium–High | Medium |

| Long-Term Cost Efficiency | High-volume printing | Balanced | Critical applications | Visual needs |

| Typical Use | Shelf labels | Shipping labels | Chemical labels | Promotional labels |

Wax ribbons are ideal for high-volume, budget-oriented tasks, while resin ribbons justify their higher cost in applications requiring critical durability.

If you want to optimize your printing costs by choosing the right ribbon, DGS Printing Technologies is here to support you. A leader in labels, ribbons, and thermal transfer systems since 2000, DGS stocks all ribbon models through original imports. With products sourced from global brands such as ITW Thermal Films and Ricoh, DGS delivers tailored price/performance solutions for your business.

For detailed information and quotations, visit dgs.com.tr and get in touch.