Reduced compressed air consumption

Modulating vacuum reduces compressed air consumption by up to 80%: integrated sensors constantly measure the pressure. If necessary, the valve technology is readjusted.

Less wear and tear

Due to the motorized operation of not only the winder, but also the winder, the printing module wears out less. At the same time, the prints are extremely delicate.

No maintenance parts

The label print and apply system is built completely with no maintenance parts. Components are replaced only when necessary. Only the pressure module used in each case should be maintained in accordance with the relevant manufacturer’s specifications.

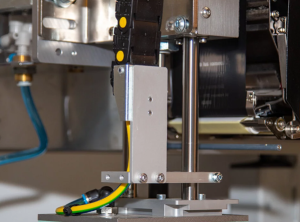

Modular Structure

The Legi-Air 4050E has a consistently modular design and can therefore be individually adapted to the requirements of the respective application. Labels can be printed with printer modules from all leading manufacturers.

Machine safety according to EN415-10

Legi-Air 4050 E meets all EN415-10 requirements as standard and is safe for the operator. For applications requiring higher dynamics than those defined as safe by the standard, the system can be extended for integration into an emergency stop system.

Industry 4.0 capability

The Legi-Air 4050 E is optionally available with an additional N-Controller. It is OPC UA enabled (Open Platform Communications Unified Architecture). With this cutting-edge Industry 4.0 interface, extended connectivity with other devices and information exchange that goes beyond simple signals are possible.

Comfortable use

The Legi-Air 4050 E can be easily operated using the multilingual 7″ LCD touch screen. Error diagnostics, productivity and maintenance status and events, among other things, can also be displayed. The pneumatics are easily accessible from outside the system and the two compressed air circuits are color coded for better separation.

Various applicators and stamps

Single-sided, double-sided or corner labeling

applicators and donation stamps are available to apply labels to products, packaging and pallets . 1-sided pallet labeling with extra-long delivery stroke or labeling of uneven product surfaces is also possible. There is a quick switch option for very fast switching to a different label format.

Pressure modules from all leading manufacturers

Print modules from all leading manufacturers are available for printing labels. Replacing the print module with another module is possible at any time without any problems, for example because it has been discontinued.

- Zebra

- Castle

- Novexx

- cab

- O’Neill

- rfid

An RFID printing module is available to program and print Smart Tags . This supports all current RFID standards (UHF). If necessary, a bad label rejection lever is also available which can be used to remove faulty labels.

- RFID printing module

- Faulty label reject unit

Software

Easily design and print barcode or RFID labels – this is possible with label printing software:

- Legitronic ©

- Nice Label

Software to automate the marking and networking of numerous production modules:

- Products

- PL Control

Donation Practitioners

- Continuous labeling and contactless application systems available

- pneumatic and servo electric drives are available depending on application requirements

- configurable microcontroller technology, i.e. elimination of costly control boards and PLC programming

- Individual applications ( e.g. hard-to-reach locations) can be solved with customer-specific designs

Dust and splash proof housing

Enclosure to integrate the system in adverse production environments with high levels of dust, humidity and/or low temperatures (heating).

Different tripods

Maximum flexibility with fixed, pivot-adjustable, mobile and/or automatic stands.

3-color alarm light

Alarm light for visual information about the status of the marking system.

1 and 2D scanners / vision systems / RFID gates

Systems for product identification, label reading, verification and label presence control.

Sensors

Various sensors for variable distribution pulse scanning or product sensors .

Performance data: Legi Air 4050E

Printing technique: Thermal transfer or thermal direct

Print resolution: 203dpi, 300dpi, 600dpi

Maximum printing speed: 400 mm/sec.

Label size compression stroke: 12.5 x 7 mm to 160 x 210 mm

Minimum label size and maximum label size: 10 x 5 mm – 160 x 350 mm, optional: 173 x 350 mm

Max . optionally available up to 1,160 mm

Donation Practitioners: 90° / 180° rotation. Donation stamp, 90° / 180° rotatable application, corner label, two-sided label, 1-sided pallet label, linear application. Distribution stroke up to 1,200 mm , high with short stroke

fast linear application, servo application, suction belt application.

Label gap at least 3 mm

Label roll and roll core Ø 300 mm (450 meters); preferred Large rolls Ø 350 mm (600 meters)

Data Interface: all common interfaces

control interface Potential-free outputs (relays), optocoupler inputs, M12 connection

Dispensing accuracy and dispensing cycle speed max . ± 0.8 mm with stopped product, opt . ±0.5mm; 240 labels/ min

Print Delivery Activation: Reflex sensor , light barrier, inductive or capacitive sensor , micro switch, potential-free contacts (PLC)

Diagnostic function: Via display and USB/Ethernet software

Alarm device standard Error message on 7″ LCD screen, potential-free contacts (SPS)

Options: RFID, quick-change stamp, spring-loaded dispensing stamp, alarm light, protective housing with IPC ( opt . heating), tag control, vision systems, sensors , variable dispensing pulse scanning, tripods

Power supply: 92 – 263VAC / 50~60Hz, 5 amps

Weight and Dimensions ( HxWxD ): From 75 kg; 584x765x709mm

Compressed air connection: 6 bar (clean, dry, oil-free according to DIN ISO 8573-1)

Compressed air consumption: 0.1 to 3 l per donation cycle

Ambient temperature: 2 to 35°C

Relative humidity: 15% to 95% non -condensing

Printing unit: Flexible printing module technology, e.g. Datamax , Sato , Zebra, Avery , CAB

Allow: CE mark